Reducing Emissions is not only Good Business, it's the Right Thing to do in our Communities

CNX Midstream group reduces methane emissions in Mamont, Westmoreland County, PA

December 27, 2024

By Positive Energy Hub Staff

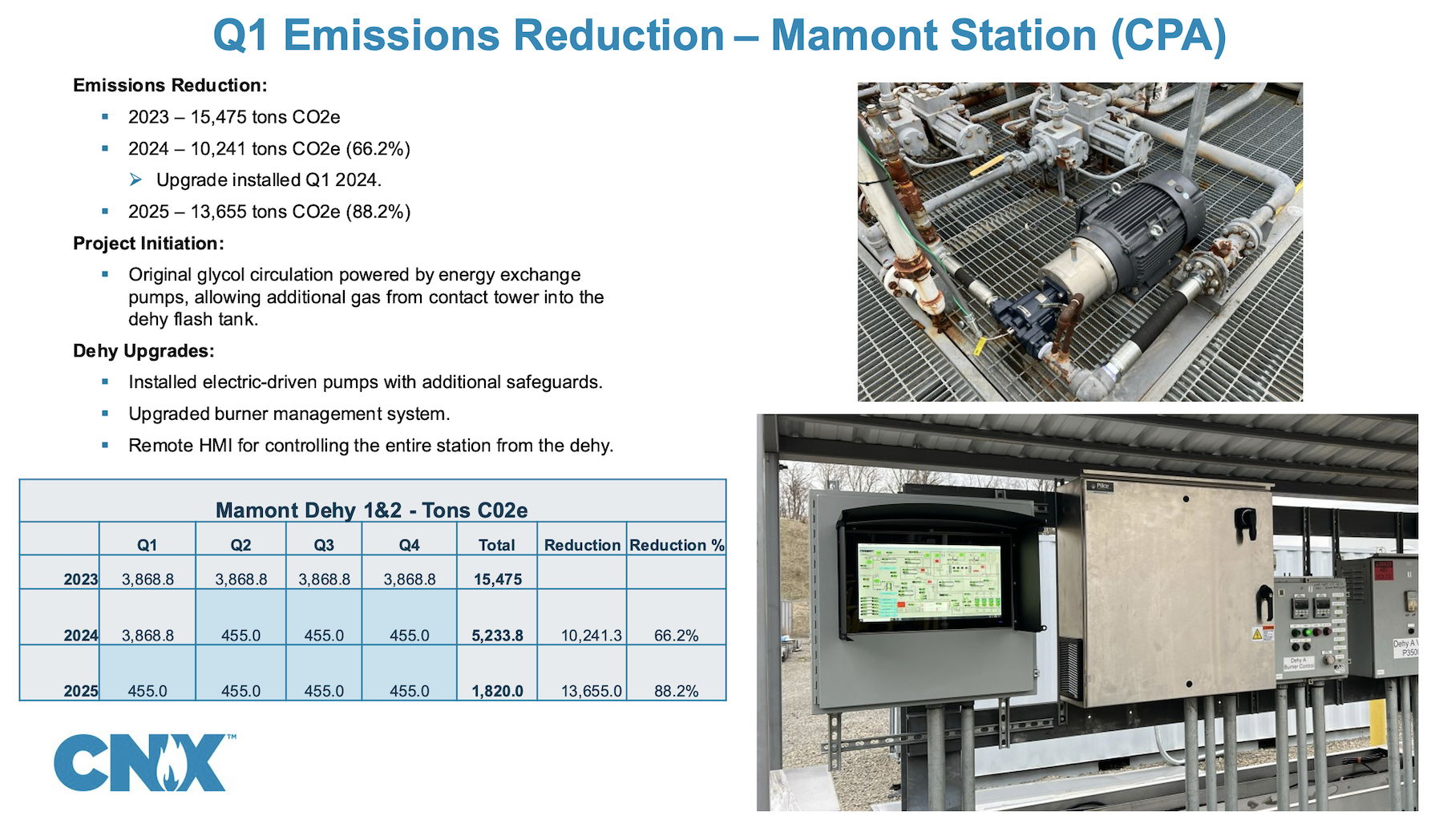

From 2020 through 2023, CNX reduced the methane intensity in our company-wide gathering and boosting segment by 31% through continuously analyzing systems and identifying opportunities for enhancements. In 2024, the company invested an additional $5 million into methane reduction efforts, with a goal of eliminating 85,000 tons of CO2e. The Midstream group made significant progress toward that number by upgrading one of its compression facilities.

Mamont Compressor Station gathers gas from well sites in northern Westmoreland County and southern Indiana County. The facility currently moves approximately 30 million standard cubic feet of gas per day. Untreated gas comes into the facility at low pressure (~125-150psi) and is saturated with water. Before the gas can be sold to downstream customers like utility companies, it needs to be compressed to meet pressure requirements (~800-900psi), and most of the water must be removed.

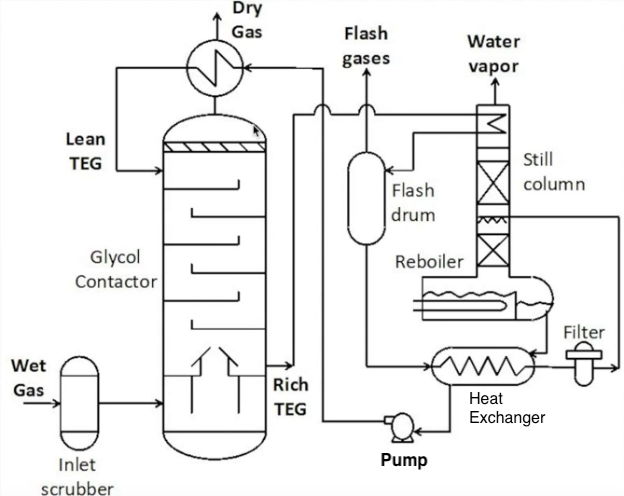

To remove the water, the facility has two dehydration units. Currently only one unit is running at any given time, while the other serves as a backup. Each dehydration unit (dehy) uses triethylene glycol to remove water from the gas stream. The dehy is a regenerative system that circulates glycol, pulling water from the gas and then boiling that water out of the glycol.

The gas and glycol flow in opposite directions through a contact tower where the glycol pulls water from the gas stream. The dry gas can then flow to sales while the saturated glycol must be regenerated to remove the water. The glycol/water mixture goes through filtration and enters a reboiler, which heats the mixture to boil off the water. Then the dry glycol is ready to be circulated back to the contact tower to start this process over again.

The glycol leaving the reboiler requires a pump to send it back to the contact tower. The original glycol pump is an energy-exchange style pump, which brings a small amount of methane along with the glycol returning from the contact tower. At older stations like Mamont, this methane is captured in the flash tank and then released into the atmosphere.

Newer dehys use electric-driven pumps that allow the contact tower to hold a higher liquid level. This means the only methane that returns to the flash tank is a very small quantity of gas entrained in the rich glycol. Mamont was identified as one of the highest methane-emitting midstream facilities in all of CNX operations at a calculated rate of 15,475 tons CO2e per year. The installation of electric-driven pumps eliminated the void where methane could enter the pump from the contact tower. As a result, the team was able to reduce dehy methane emissions at the station by 88%.

In addition, the team improved safety and reliability by installing additional automation and upgrading the burner management system. They also added a control panel at the dehy skid where the plant operator can control the entire facility.

Mamont Station is also part of the Radical Transparency initiative whereby realtime air quality reports are provided at this and other CNX facilities across southwest Pennsylvania. To see the live data, visit CNXRadicalTransparency.com.

You May Also Like...