East Street BBQ Company Gets a Taste of CNX’s Core Values

The two main components of the smoker built for East Street BBQ—the barrel and the firebox—originated as scrap pieces from the CNX MAM14 well pad.

October 17, 2025

By Positive Energy Hub Staff

John Reilly, owner of East Street BBQ Company in Greensburg, PA, has always had a passion for BBQ. In 2024, that passion paid off when he won first place at The Mad Scientist BBQ contest. The top prize? A week studying under several pit masters in Houston, Texas. When he returned, he decided to turn his dream into reality and start his own BBQ company.

But John faced a significant challenge: in the BBQ world, pit masters are judged by their custom smokers, and acquiring one large enough to support a business is both difficult and expensive. He reached out to his friend Christopher Benamati, CNX Manager of Facilities Construction from Indiana, PA, hoping Chris could point him toward a local fabricator willing to take on the custom build at a reasonable price.

Chris’s response? He offered to build it himself.

Over the summer, Chris dedicated most of his weekends to the project, investing roughly 100 hours of hands-on fabrication. Working without automated equipment, he cut and welded everything by hand—encompassing multiple disciplines of metal fabrication and welding, including the East Street BBQ emblems. He built almost all the parts in-house, sourcing 100% American-made materials and collaborating with CNX partners throughout the process.

This wasn’t just a favor between friends—it was a demonstration of CNX’s core values in action. Chris's decision to take full ownership of such a challenging project, donating his time, skill, and resources, exemplifies true responsibility. He didn't just point John in a direction; he committed himself to building a solution and helping a local entrepreneur succeed. This embodies the CNX core values of Responsibility, Ownership, and Excellence, as well as the CNX micro-TIL commitment.The attention to detail and collaboration with CNX partners speak to the pursuit of excellence and showcase the CNX Appalachia First vision. The result isn't just a smoker—it's a testament to craftsmanship, community support, and pride in work that helps local businesses thrive.

Smoker Construction Timeline

By Christopher Benamati, Manager of Facilities Construction

Start of the Journey

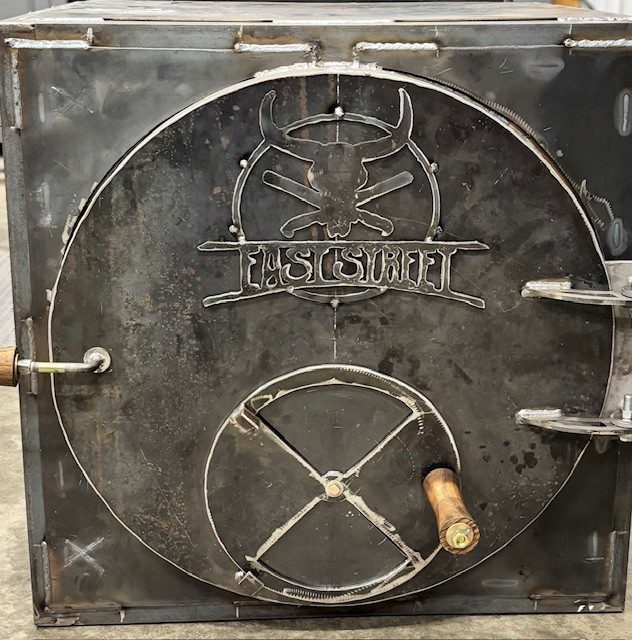

The two main components of the smoker (the main cooking chamber or "barrel" and the smoke chamber or "firebox") started their lives as scrap pieces from the MAM14 Utica conductor string. The conductor casing is 30" in diameter and has a wall thickness of 3/8". At 118 pounds per foot, these two pieces have a combined weight of over 1,400 lbs!

Keith Coleman, CNX Drilling Director, donated these two pieces, and then they were hauled off the location by James White Excavating. The material was later picked up and loaded at their shop in Spring Church, PA. JWE donated their time and equipment.

Fabrication Begins

Once the material arrived at my shop in Homer City, PA, I began with the basic layout of the main chamber. No CAD drawings here. A lot can be accomplished with very basic tools, such as soapstone, tape measures, painter's tape, a compass, basic math, and simple geometry.

The steel plate and other structural steel were purchased at Kovalchick Corporation in Indiana, PA. We insisted on USA-melted and manufactured steel ONLY. This plate was originally manufactured at NUCOR. The angle and channel were manufactured at U.S. Steel, prior to it being sold to Nippon, a Japanese-based company.

Initial Cuts and Sandblasting

The door openings were partially cut out, and door reinforcement was tacked into place. Not cutting the doors out completely allowed for the reinforcement to be welded without distorting the doors. Later, the doors were cut free from the inside out using a grinder and a cutoff wheel. Straps were made using material cut from the smokebox, which had the same radius. Doing it this way saved the cost of having the straps rolled in a plate roll.

Once this process was complete, the main chamber and smokebox were sent to sandblasting to help ensure weld quality during later fabrication and to remove the bituminous coating used to protect the casing.

Sandblasting was performed at Wood Crest Point, located in Homer City, PA. Wood Crest Point has worked with CNX in the past and donated the material and labor for this process.

Smokebox Fabrication

Through some research, I found out that a lot of prior engineering has gone into the design of offset smokers. The ratio of smokebox volume to main chamber volume is critical. The smokebox calculates out to be roughly 30% of the main chamber volume.

The smokebox features a fully opening front door, providing ease of loading and cleaning. The pinwheel was plasma cut by hand, with the openings being ground smooth using a die grinder. Simple stops were created using angle iron, and the latch system is a simple cam design I created using angle and Grade 8 bolts that were heated and bent. The wooden handles were made from an old horse-drawn plow handle that was turned down on a hand lathe and shaped using a wood file.

The door hinges were the only metal parts not fabricated in-house. They were purchased from Mystic Smokers, a Georgia-based fabrication company. Mystic's owner is a friend of John's and produces these parts on a laser-guided plasma table.

The Moment of Truth

Joining the main chamber and the smoke chamber was a significant moment in the fabrication process. Up to this point, I was able to roll the chambers around by hand as I cut and welded. Once the two chambers were joined, the whole thing had to be moved by machine. It also meant that I would be welding out-of-position for a lot of the remaining welds.

Before this step, I had done extensive planning to minimize out-of-position welding as much as possible.

The end plate and smoke collector were two components I ensured were welded into place before attaching the two large chambers. Like the smokebox, the smoke collector is designed to occupy a specific volume within the main chamber. Its location is also critical to the internal rack location to draw the smoke directly over the food.

Custom Trailer

The original plan was to put the smoker on a box store utility trailer to save time on the build. After spending many hours hating the idea of a custom smoker on a box store trailer, I decided to build my own.

The idea for the trailer was to give it a "hotrod" vibe. I opted for a spring-under-axle design to keep the deck low to the ground, and the wrap-around fenders were slung low to the tires. The whole smoker was "frenched" into the frame. At the end of the build, we added the powder-coated rims and wide white tires.

This was not my first trailer build. When I got out of the Marines, I built trailers at a local trailer manufacturer while I went to school for Welding Engineering.

Trailer parts were purchased locally at New Alexandria Tractor Supply in New Alexandria, PA (the same place I worked building trailers during college). We went with an American-made, high-quality Dexter Axle. The owner gave us a significant discount on the material, wanting to contribute to a local upstart and understanding the challenges that come with that.

Smokestack Fabrication

The smokestack is another engineered component on the smoker. Pipe diameter is relative to the overall volume of the smoker. For a 275-gallon smoker, an 8" smokestack is recommended.

A lot of time and "weld shop engineering" went into the smokestack, from the rebar lever-operated cap to the hinge and securing hardware systems. It was also an opportunity to switch from the GMAW welding process used throughout most of the build to the GTAW process (better known as "TIG") to join stainless to carbon material.

Keith Orkis of Orkis Ironworks donated the stainless material for the smokestack. Orkis Ironworks is a CNX partner and builds small fabrications for the Facilities Construction team. This piece of stainless pipe was leftover from an autoclave project at the old Heinz plant in Pittsburgh.

Smoker Doors

The smoker doors required more weld shop engineering. After the door reinforcement and rolling handles were welded, the doors were finally cut free, allowing them to open. With each door weighing over 100 pounds, counterweights were added to allow the doors to open easily.

The target was to find a position where counterweights would allow the doors to open easily, but not flop open when bouncing down the road. Using a simple crane scale, we achieved a position where the "felt weight" is roughly 25% of the actual weight.

The weights were originally culvert covers from the CNX Aikens well pad that I cut in half. James White Excavating removed them during a clean-up project and donated them to the build.

Custom Touches

To give the smoker an additional level of customization, East Street BBQ emblems were plasma cut by hand and added to the smokebox door and the main chamber door counterweights.

Final Product

After roughly 100 fabrication hours, final trailer painting, and the application of linseed oil to the bare metal components, we finally had a smoker that was ready for business!

Many thanks to CNX and all the CNX partners who contributed to the project. Without your help, this project would not have been such a success!

Sincerely,

Chris Benamati